In a steel plant, each facility is intricately interconnected with others through energy, material, and product flow. To ensure seamless coordination and optimization of these interconnected processes, an effective information network is indispensable across three key organizational levels: plant operations, production control, and administrative control. This network should encompass robust communication systems for various critical components, including:

• Ladle crane communication

• EOT cranes in the Steel Melting Shop, Casting, Slab Yard, Charging Bay Rail Mill, Coil Yard

• Blast furnace operations such as the Mud Gun, Tap Hole Drilling

• Intelligent CCTV Surveillance and Vigilance

• Torpedo loco Tracking

• Stacker Reclaimer and conveyor belt management

• PA (Public Address) systems

• Wagon tracking

• Coke oven management

• AAQMS Pollution monitoring

The information network must be capable of collecting and integrating data from all these systems, making it accessible to operators and decision-makers in real time. This capability will enable continuous monitoring and timely adjustments, ensuring the plant operates efficiently and safely.

Industrial Critical Communication Solutions

Critical Connectivity Solution for Stacker Reclaimer and Conveyor Belt

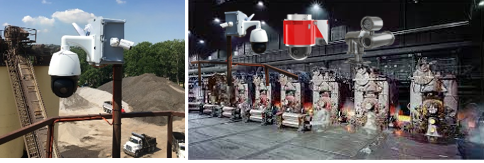

Intelligent CCTV Surveillance and Vigilance

Wireless Radio Remote Controls Solution for E.O.T Cranes

E.O.T Cranes – steel melting shop, casting, slab yard, mill, coil